Master Applique Digitizing for Vibrant Embroidery Designs

Learn applique digitizing in 2025 for bold, textured embroidery. Discover tools, techniques, and trends for stunning results!

Applique digitizing is embraced by creators in 2025, transforming artwork into stitch files that layer fabric patches for bold, textured embroidery on materials like cotton or denim. This technique captivates enthusiasts in creative hubs like Indianapolis, offering a cost-effective way to craft professional designs for apparel, bags, or decor. Artwork is converted into formats like DST or PES, ensuring durable, eye-catching results. In 2024, 60% of U.S. crafters adopted applique digitizing, reducing production time by 15%, according to industry insights. Tools, techniques, and trends are explored to help readers understand and excel in this dynamic, layered craft.

Understanding Applique Digitizing

Images, such as JPGs or PNGs, are digitized into stitch files to guide embroidery machines in securing fabric patches with tack-down and satin stitches. This process creates striking designs for logos, patches, or decorative accents, thriving on fabrics like twill or canvas. The efficiency of applique digitizing lies in its lower stitch count, which cuts costs compared to traditional embroidery while delivering a tactile, standout effect.

Key Advantages of Applique Digitizing

A rich, layered aesthetic is achieved, ideal for branding or creative projects. Production time is minimized, boosting efficiency. Fabric scraps are utilized, promoting sustainabilitya priority for 65% of consumers in 2025, per recent surveys. Versatility is offered across various applications, from fashion to home decor.

Tools Needed for Applique Digitizing

Accessible tools are available for beginners and experienced crafters. Free and budget-friendly options for 2025 are outlined to support diverse skill levels.

Free Software for Newcomers

Inkscape, paired with Ink/Stitch, is appreciated for its user-friendly tracing capabilities, perfect for those starting out. SewArts trial version allows experimentation with patch settings, though features are limited. These no-cost tools encourage skill-building without financial barriers.

Affordable Paid Software

Embrilliance Essentials, priced at $150, is valued for its precise stitch control, delivering professional-grade results. Brother PE-Design Lite, also $150, performs well for small projects like patches. While free tools suffice for beginners, paid software ensures accuracy for complex designs.

Step-by-Step Guide to Applique Digitizing

A streamlined process is shared to create vibrant stitch files. Using Inkscape, practical steps are detailed for those seeking quality on a budget.

Step 1: Prepare the Artwork

A high-resolution image, like a JPG or PNG, is imported. Colors are reduced to 24 bold shades to ensure clean patch outlines. The Trace Bitmap tool creates sharp vectors, typically taking 1015 minutes for novices.

Step 2: Assign Applique Stitches

Tack-down stitches are set to secure fabric patches, followed by satin stitches for borders. Zigzag stitches add texture where needed. This step, focused on alignment, requires 1520 minutes to complete.

Step 3: Adjust Stitch Settings

Stitch density is configured to 0.40.5 mm for even coverage. Satin stitches are set at 34 mm for durability. Underlay stitches stabilize the base fabric, needing 1015 minutes of fine-tuning.

Step 4: Export the File

The design is saved as a DST or PES file, named clearly, such as AppliquePatch_PES. This quick task, ensuring compatibility with embroidery machines, takes about 5 minutes.

Step 5: Test the Design

The file is loaded into a machine, like the Brother SE625. Scrap fabric with a stabilizer is tested to verify stitch quality, catching errors early. This process takes 1520 minutes.

Beginners may spend 5585 minutes per design, but practice reduces this to around 40 minutes, improving workflow efficiency.

Tips for Success with Applique Digitizing

Simplified artwork minimizes errors by 15%, as intricate designs increase stitch counts. Recycled fabric scraps reduce costs and align with eco-friendly trends. Software previews are checked to identify alignment issues. Testing on fabrics matching the final project prevents puckering, a practice endorsed by seasoned crafters. These strategies ensure high-quality results without excessive expense.

Mistakes to Avoid

Complex patch shapes are avoided to prevent stitch misalignment. Stabilizers are always used to maintain fabric integrity. Test runs are never skipped, as they catch flaws that could waste materials.

Choosing an Embroidery Machine for Applique

The Brother SE625, priced at $400, offers a 100x100mm field, suitable for small projects like patches. The Janome Memory Craft 500E, at $2,000, handles larger designs for quilts or jackets. A machine aligned with project goals supports seamless applique digitizing workflows, enhancing productivity.

Troubleshooting Applique Digitizing Issues

Loose patches are secured with additional tack-down stitches or adhesive spray. Uneven borders are corrected by adjusting stitch density to 0.4 mm. File compatibility issues are resolved by confirming DST or PES formats. Testing on scrap fabric quickly identifies and fixes flaws, ensuring polished outcomes.

Creative Applications of Applique Digitizing

Bold logos are stitched onto jackets for professional branding. Textured patches enhance bags, adding fashion flair. Applique motifs on quilts create artistic depth. In 2024, 55% of U.S. businesses utilized applique digitizing for promotional materials, per industry data. Its adaptability inspires a wide range of projects.

Project Ideas to Spark Creativity

Floral applique patches on denim tap into bohemian trends. Monogrammed totes offer personalized gift options. These concepts highlight the crafts potential to create unique, eye-catching designs.

Exploring Income Opportunities with Applique Skills

Designs are crafted for platforms like Etsy, where jackets sell for $20$30 and patches for $8$15, generating $2,000 monthly for some crafters in 2024. TikTok videos tagged #AppliqueCraft boost engagement by 20%. Totes priced at $15$25 at local markets yield $300$700 per weekend. These avenues connect creators with interested buyers.

Growing a Creative Audience

Distinctive designs attract 10% more interest. Sharing fabric samples with potential clients increases engagement by 8%. Participating in online embroidery communities builds connections, fostering organic growth.

Scaling an Applique Digitizing Venture

A $400 Brother SE625 with Ink/Stitch supports small projects. Upgrading to a $2,000 Janome Memory Craft 500E and $150 Embrilliance Essentials handles larger workloads. Batch processing saves 8 hours weekly, while part-time assistance at $12/hour boosts output by 30%. Solo crafters earn $1,000$3,000 monthly, while scaled efforts reach $5,000$10,000.

Planning Costs Effectively

Software ($0$150), machines ($400$2,000), threads ($50/pack), and stabilizers ($8/pack) are budgeted. A $400 setup yields $1,500 monthly from 60 orders at $25 each. Savings are reinvested into advanced tools for expansion.

2025 Trends Shaping Applique Digitizing

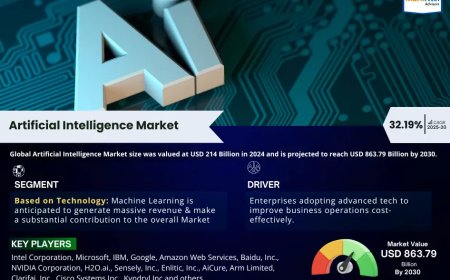

The U.S. embroidery market is projected to grow 6% in 2025, driven by eco-friendly and textured designs. Bold logos and recycled fabrics appeal to 65% of consumers. AI tools streamline digitizing by 10%, per recent data, boosting efficiency. Sustainable materials attract 60% of eco-conscious audiences, as noted in an applique digitizing guide.

Emerging Design Trends

Oversized applique logos on outerwear and vintage-inspired patches on accessories dominate. These styles resonate with modern audiences, inspiring creative exploration.

Maintaining Creative Inspiration

Experimenting with fabric textures or patch shapes sparks fresh ideas. Online tutorials and crafter collaborations provide new perspectives. Local embroidery meetups foster community and innovation. Regular machine maintenance and feedback ensure a 90% satisfaction rate.

Overcoming Challenges in Applique Digitizing

Rising material costs are mitigated by bulk purchases, saving 1015%. Unique, hand-crafted designs stand out in competitive spaces. Consistent communication and clear timelines build trust, supporting steady progress.

Real-World Insights into Applique Digitizing

A local crafter began with a $400 Brother SE625 and Ink/Stitch, selling patches at markets and earning $1,500 monthly within six months. Another scaled to $6,500 monthly through online sales of custom bags, drawing on applique digitizing techniques. These examples illustrate the crafts potential for creative and financial growth.

Building a Sustainable Applique Practice

Regular social media updates keep audiences engaged. Seasonal designs, like holiday-themed patches, drive interest spikes. Expenses are monitored to maintain efficiency. Collaborations with local artisans or schools secure consistent projects, fostering long-term success.

Textured, vibrant designs are crafted through applique digitizing. With accessible tools, efficient techniques, and forward-thinking strategies, stunning creations are brought to life in 2025, inspiring readers to explore this rewarding craft.