Polycaprolactone Market: Biodegradable Innovation Reshaping Medical and Industrial Applications

The polycaprolactone market is expected to witness market growth at a rate of 10.8% in the forecast period of 2021 to 2028

Introduction Polycaprolactone (PCL) is a biodegradable polyester known for its low melting point, biocompatibility, and versatility across industries. From medical implants to sustainable packaging, PCL is gaining traction as a functional alternative to conventional polymers. As global demand for eco-friendly materials intensifies, the PCL market is witnessing robust growth driven by innovation, regulatory support, and expanding end-use applications.

The Evolution PCL was first synthesized in the 1930s, but its commercial relevance emerged decades later with applications in biomedical engineering and polymer blending. Initially used in drug delivery and sutures, PCL evolved through ring-opening polymerization techniques to produce high-purity grades suitable for 3D printing, tissue scaffolds, and thermoplastic polyurethane (TPU) formulations. Recent developments include nanosphere and microsphere formats for controlled drug release and regenerative medicine.

Market Trends

-

Biodegradable Packaging Demand: PCL is increasingly used in compostable films and flexible packaging, aligning with circular economy goals.

-

Healthcare Expansion: Applications in wound care, drug delivery, and tissue engineering are driving adoption in medical-grade PCL.

-

3D Printing Integration: PCL filaments are favored for orthopedic and dental applications due to moldability and low processing temperatures.

-

TPU Blending: PCL enhances flexibility and durability in TPU products used across footwear, electronics, and automotive sectors.

-

Sustainable Manufacturing: Companies are investing in bio-based PCL production to reduce carbon footprint and meet ESG targets.

Challenges

-

Thermal Limitations: PCLs low melting point (~60C) restricts its use in high-temperature environments.

-

Mechanical Strength Constraints: Limited load-bearing capacity affects its suitability for structural applications.

-

Cost and Scalability: Production costs and raw material availability pose challenges for mass adoption.

-

Regulatory Complexity: Varying standards across regions complicate product approvals and market entry.

-

Competition from Polyols: Polycaprolactone polyols offer similar benefits at lower costs, especially in coatings.

Market Scope

-

By Form:

-

Pellets

-

Nanospheres

-

Microspheres

-

-

By Production Method:

-

Ring-Opening Polymerization

-

Polycondensation of Carboxylic Acid

-

-

By Application:

-

Thermoplastic Polyurethane (TPU)

-

Healthcare (Drug Delivery, Sutures, Tissue Engineering)

-

Packaging

-

Coatings & Adhesives

-

3D Printing

-

-

By Region:

-

North America

-

Europe

-

Asia-Pacific

-

Latin America

-

Middle East & Africa

-

Asia-Pacific leads in production and consumption, driven by industrial growth and sustainability initiatives. North America is expanding rapidly due to healthcare innovation and 3D printing adoption, while Europe benefits from strong regulatory support for biodegradable materials.

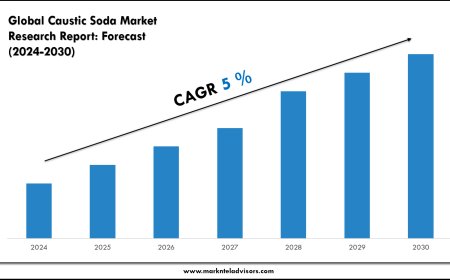

Market Size The global polycaprolactone market was valued at approximately USD 703.5 million in 2025 and is projected to reach USD 1.42 billion by 2032, growing at a CAGR of 10.6%. Healthcare and TPU applications dominate revenue share, with pellets as the most widely used form due to processing ease.

Factors Driving Growth

-

Biodegradability and Biocompatibility: PCLs eco-friendly profile supports adoption in medical and packaging sectors.

-

Material Versatility: Compatibility with other polymers enhances its utility in blends and composites.

-

Healthcare Innovation: Rising demand for bioresorbable implants and drug delivery systems boosts market expansion.

-

3D Printing Boom: Customizable, low-temperature filaments make PCL ideal for personalized medical devices.

-

Sustainability Mandates: Regulatory pressure and consumer demand for green materials fuel adoption.

-

R&D Investment: Companies are developing advanced PCL grades for niche applications like osteobotics and bioelectronics.